Model No.: 30mm

High Density Alumina Grinding Media Ball

Ruineng Grinding Balls are suitable for grinding medium used in ball grinding machines.

The alumina balls’ wear-resistance is higher than the common alumina balls’. When it is working, the ball won’t pollute the grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

The high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.

| Main material | AL2O3, bauxite, roller powder, industrial alumina powder, high-temperature calcined alumina powder and other materials. |

| Feature | l Suitable hardness. l Suitable density. l Good wear resistance. l Strong corrosion resistance. l Higher wear efficiency than natural flint and pebble. l Avoid metal impurities. l Low price. l High strength. l Small volume. l Pollution free. l Alumina content percentage: 60% - 65% alumina as medium alumina balls, 75% - 80% as medium high alumina balls, and above 90% alumina balls. The above 90% alumina balls are subdivided into 90 porcelain, 92 series and 95 series as well as 99 series. In consideration of high cost, 99 series of alumina balls are rarely manufactured in large quantities by large-scale company, it mainly produced by hand in some special ceramic factories. |

| Application | It is mainly used as grinding medium for grinding and processing of white cement, minerals, ceramics, electronic materials, magnetic materials, coating, paint and other raw materials. |

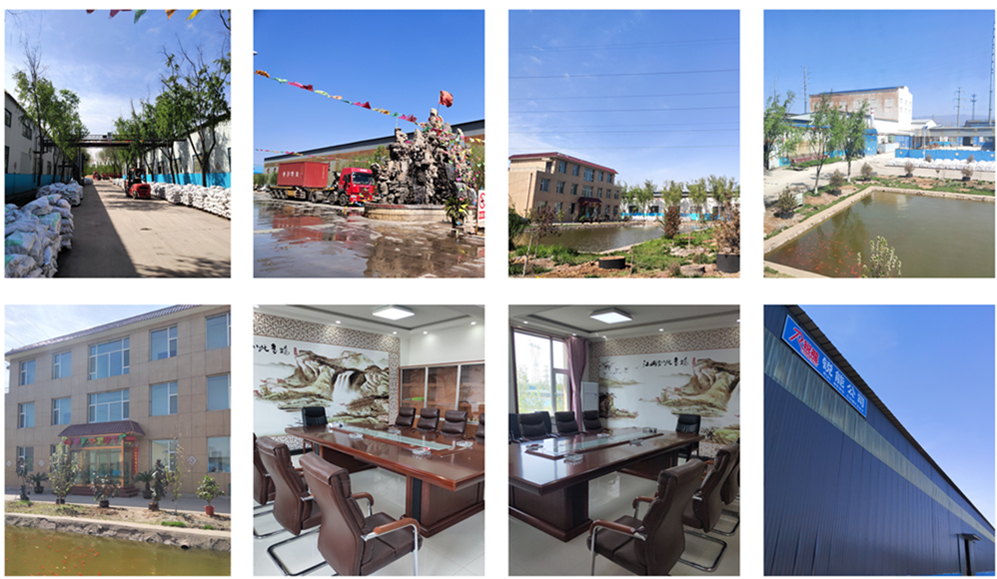

Shanxi Ruineng Ceramic Material Ltd. is one of the earliest professional manufacturers specializing in the production of ceramic abrasive materials in China. It has a development history of more than 20 years. It is a member of China Construction and health Ceramics Association, provincial high-tech enterprise, provincial energy-saving development demonstration enterprise and provincial safety production demonstration enterprise. It has passed the ISO9001 quality management system certification. The company mainly produces Alumina Brick and Alumina Ceramic Ball30-60mm.Annual output 150000tons.Products are exported to India, Vietnam, Pakistan, Malaysia, Indonesia and other countries.

The company is located in the industrial park of Jiaocheng County, Luliang City, Shanxi Province, covering 600 acres, 180 million RMB in fixed assets, more than 600 employees, including 90 technical personnel, with an annual output value of 200 million RMB. The company fully implements the scientific management of the whole process of production and operation, and has the domestic advanced production equipment, the precise indextechnic index, and high-quality products to meet the domestic and foreign customers’ needs.

The business philosophyis: "based on Shanxi, facing the whole country, going to the world", carrying forward the enterprise spirit of honesty, truth and pragmatism, scientific and technological innovation. Company will constantly adjust the product structure, meet the needs of the market, and provide competitive products and services.

Compress machine

Our company currently has 12 sets of large tonnage and most advanced isostatic ball compress machine in china and 2 brick compress machine, which have the advantages of high pressure, good molding, high strength and high efficiency.

Kiln

Our company currently has one 360-meter ultra-long ultra-wide roller kiln and two 160-meter roller kiln, achieving a daily output of 450 tons. This equipment has the advantages of small temperature difference, uniform firing, good porcelainization, stable density, large output and high data utilization rate

Water Mill Machine

Our company has 36 sets of 40-ton water mills machine, which is the most efficient grinding equipment in the industry. It is divided into two processes, coarse grinding and fine grinding. The final fineness is 500 mesh, which guarantees the fineness of ingredients and the stability of product quality.

Spray tower

Our company has one 10,000-type spray tower and two 3000-type spray towers to ensure the strength of the powder and the uniform granulation.

Rotary kiln

Our company has 2 large-scale rotary kiln with a daily output of 600 tons of clinker, which can fully guarantee the self-supply of clinker.

Product Categories : Ceramic Ball > Ceramic Ball 30